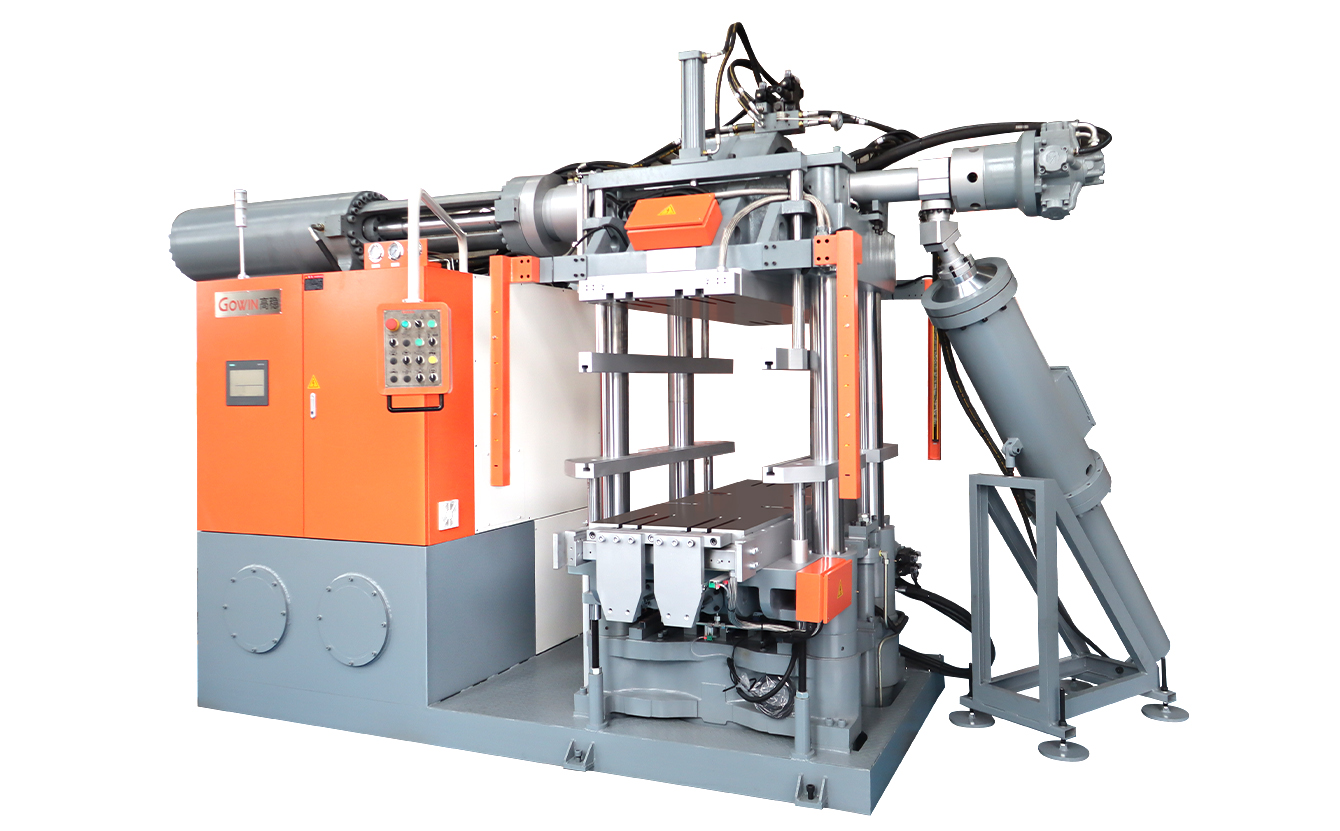

Lefatšeng la phetisetso le kabo ea matla, polokeho le ts'epo ea motlakase ke tsa bohlokoahali. Ho netefatsa lisebelisoa tse phahameng le tse tšoarellang nako e telele, bahlahisi ba itšetlehile ka likarolo tsa boleng bo phahameng joalokali-insulator tsa siliconeletse tšoarang lehalima. Empa na u kile ua ipotsa hore na likarolo tsee tsa bohlokoa li etsoa joang? Karabo e fumaneha ho theknoloji e tsoetseng pele:Mechini ea ho etsa ente ea silicone e tiileng ea mmuso.

Sengoliloeng sena, re tla shebisisa hore na mechini ea ente ea silicone ea boemo bo tiileng e sebetsa joang, le hore na ke hobane'ng ha e le bohlokoa haholo bakeng sa ho hlahisa li-insulators tse tšoarellang le tse tšoarang lehalima tse sireletsang lisebelisoa tsa rona tsa motlakase.

Mochini oa Ente ea Silicone oa Naha ke Eng?

Mochini oa ente ea silicone ea boemo bo tiileng ke sesebelisoa se ikhethileng se sebelisetsoang ho hlahisa likarolo tse entsoeng ka rabara ea silicone ea viscosity e phahameng. Rabara ea silicone e sebelisoa haholo indastering ea matla ka lebaka la thepa ea eona e ntle ea ho kenya motlakase, ho hanyetsa boemo ba leholimo, le bokhoni ba ho mamella mocheso o feteletseng.

Mochine o sebetsa ka ho futhumatsa le ho kenya silicone e tiileng-state (high-viscosity) ka har'a hlobo, moo e pholileng le ho tiisa sebopeho se lakatsehang. Ts'ebetso ena e hloka ho nepahala, kaha silicone e tlameha ho phalla ka mokhoa o ts'oanang ka har'a hlobo ebe e etsa likarolo tse nang le mamello e thata, ho netefatsa hore li finyella litekanyetso tse phahameng tse hlokahalang bakeng sa lisebelisoa tsa matla.

Mechini ee e Sebetsa Joang?

1. Tokisetso le ho Kopanya lintho tse bonahalang:

Pele ho ente, rabara ea silicone e tsoakoa le lisebelisoa tse phekolang le li-additives tse ling ho netefatsa hore e kopana le thepa e lakatsehang, joalo ka ho kenya motlakase le ho hanyetsa boemo ba leholimo.

2.Heating le Extrusion:

Thepa ea silicone e futhumatsa mocheso o itseng, e fokotsa viscosity ea eona e le hore e ka phalla habonolo ka har'a hlobo. Silicone ea boemo bo tiileng e fetisoa ka mochini oa screw kapa piston mochining oa ente.

3. Ente ka Molds:

Silicone e futhumetseng e kenngoa ka har'a liforomo tse nepahetseng moo e nkang sebopeho sa karolo e lakatsehang, joalo ka insulator kapa khetla e thibelang lehalima. Ts'ebetso ea ho bopa e bohlokoa hobane likarolo li hloka ho nepahala ka mokhoa o phethahetseng bakeng sa ts'ebetso e nepahetseng.

4. Ho Fokotsa le ho Pholisa:

Hang ha silicone e kenngoa ka har'a hlobo, e etsa mokhoa oa ho phekola (phekolo ea mocheso), e tiisang thepa. Nako ea ho phekola le mocheso li laoloa ka hloko ho netefatsa ts'ebetso e nepahetseng.

5. Demolding le Tlhahlobo:

Ka mor'a ho pholile, karolo e tlosoa hlobo. Liteko tsa taolo ea boleng li netefatsa hore sehlahisoa sa ho qetela se kopana le litekanyetso tse hlokahalang bakeng sa ts'ebetso ea motlakase, matla a mochini, le ho tšoarella.

Hobaneng Mechini ea Ente ea Silicone ea Solid-State e le Bohlokoa Khoebong ea Matla?

Tšebeliso ea silicone ka thepa ea phetisetso ea matla joalokali-insulatorletse tšoarang lehalimae se e le ea bohlokoa. Ke ka lebaka lena:

Insulation ea Motlakase:

Li-insulators tsa silicone li thusa ho boloka polokeho le katleho ea lithapo tsa motlakase ka ho thibela ho tsoa ha motlakase, esita le maemong a phahameng a matla. Mochini oa ente ea silicone ea boemo bo tiileng o etsa bonnete ba hore li-insulators tsena li hlahisoa ka thepa e nepahetseng ea motlakase e khonang ho mamella maemo a leholimo a feteletseng le khatello ea motlakase.

Maemo a Leholimo:

Mehaho ea motlakase e tlameha ho mamella mefuta eohle ea mathata a tikoloho—mocheso o feteletseng, pula ea litloebelele, lehloa, esita le mahlaseli a kotsi a tsoang letsatsing. Rabara ea silicone, ka lebaka la khanyetso ea eona e ntle ea boemo ba leholimo, ke sesebelisoa sa ho sireletsa le ho sireletsa lisebelisoa tsa motlakase libakeng tse kantle. Mechini ea ente e tiisa hore thepa ena e kentsoe karolong e 'ngoe le e 'ngoe e hlahisoang.

Matla a Mechini le Tšireletseho:

Li-insulators le tse tšoarang lehalima li hloka ho mamella khatello e phahameng ea mochini (mohlala, tsitsipano, tšusumetso) ho kenyelletsa khatello ea motlakase. Mechini ea ente ea silicone ea boemo bo tiileng e netefatsa hore silicone e sebelisitsoeng e na le botsitso bo nepahetseng ba matla, ho tenyetseha le ho tšoarella.

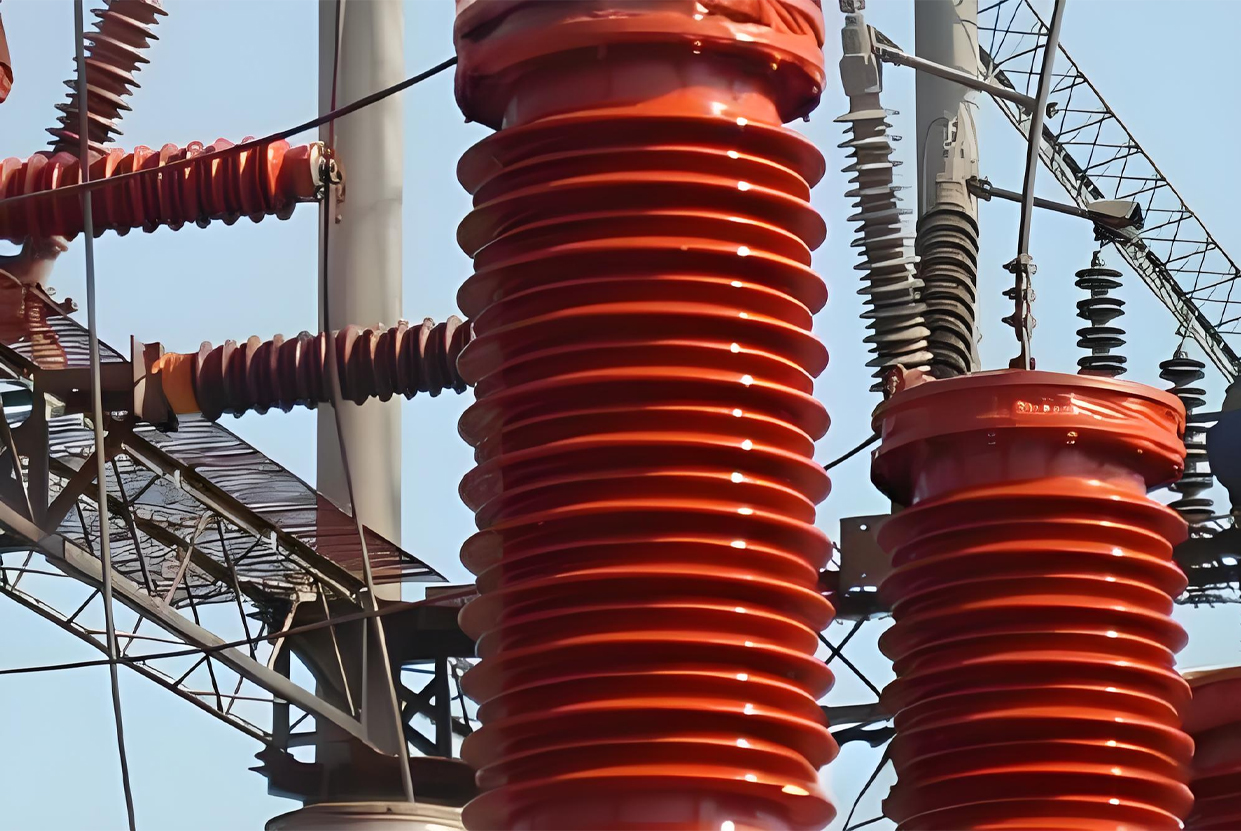

Likopo ho Li-Insulators le Lits'oaruoa tsa Lehalima

Li-insulators tsa silicone:

E sebelisoa lithapong tsa motlakase tse nang le matla a phahameng le li-substations, li-insulator tsa silicone li bohlokoa bakeng sa ho thibela ho tsoa ha motlakase le ho netefatsa phetisetso ea matla e tšepahalang. Mokhoa oa ho bopa ente o hlahisa li-insulators tse nang le bokaholimo bo boreleli bo fokotsang kotsi ea ho bokellana ha litšila le ho ntlafatsa ts'ebetso ea tsona ha nako e ntse e ea.

Batšoantšisi ba Lehalima:

Lits'oants'o tsa lehalima li sireletsa lisebelisoa tsa motlakase litlamorao tse mpe tsa ho otla ha lehalima le ho phahama ha motlakase. Rabara ea silicone e sebelisoa bakeng sa casing e ka ntle ea lisebelisoa tsena ka lebaka la tlhaho ea eona e sa sebetseng le bokhoni ba ho monya le ho qhala matla a mangata a motlakase. Mechini ea ente ea silicone ea boemo bo tiileng e hlahisa likaroloana tse thibelang lehalima tse ka mamellang ho otla ka kotloloho ha li ntse li sireletsa lisebelisoa tsa bohlokoa.

Melemo ea ho Sebelisa Mechini ea Ente ea Silicone ea Naha e tiileng Lefapheng la Matla

Ho Nepaha le ho Tšepahala:

Ka boiketsetso le taolo e nepahetseng ea li-parameter tsa ente (mocheso, khatello, lebelo), bahlahisi ba ka etsa bonnete ba hore karolo e 'ngoe le e' ngoe e hlahisoa ka mokhoa o nepahetseng, ho ntlafatsa boleng ba kakaretso le ho ts'epahala.

Sebetsa se Phahameng sa Tlhahiso:

Mokhoa oa ho etsa ente o potlakile mme o ka hlahisa likarolo tse ngata tse nang le litšila tse fokolang, tse thusang ho fokotsa litšenyehelo tsa tlhahiso le nako.

Boikemisetso:

Lisebelisoa tse fapaneng tsa motlakase li hloka libopeho tse fapaneng, boholo le likarolo tsa ts'ebetso. Mechini ea ente ea silicone e tiileng e ka fetoloa habonolo ho theha hlobo e tloaelehileng bakeng sa likarolo tse fapaneng, ho tloha ho litiiso tse nyane ho isa ho li-insulator tse kholo.

Matla a Matla:

Mechini ea sejoale-joale ea ente e etselitsoe ho sebetsa hantle, ho fokotsa khabone ea lits'ebetso tsa tlhahiso.

Qetello

Mechini ea ente ea silicone ea boemo bo tiileng e fetola tsela eo re hlahisang likarolo tsa bohlokoa tsa indasteri ea matla ka eona. Ka ho netefatsa tlhahiso e nepahetseng ea li-insulators tse sebetsang hantle haholo le tse thibelang lehalima, mechini ena e thusa ho sireletsa lisebelisoa tsa rona tsa motlakase likotsing tsa tikoloho le tsa motlakase. Ha indasteri ea motlakase e ntse e tsoela pele ho hola le ho fetoha, mechini ena e tla bapala karolo ea bohlokoa ho netefatsa hore marang-rang a rona a bolokehile, a ts'epahala, 'me a sebetsa hantle - hona joale le nakong e tlang.

Haeba u le indastering ea matla kapa u etsa lintho tsa motlakase, ho utloisisa bohlokoa ba mochini oa ente ea silicone ea solid-state ho ka u thusa ho etsa liqeto tse nepahetseng mabapi le theknoloji e tsamaisang lihlahisoa tseo re li tšepileng letsatsi le letsatsi.

Nako ea poso: Jan-03-2025